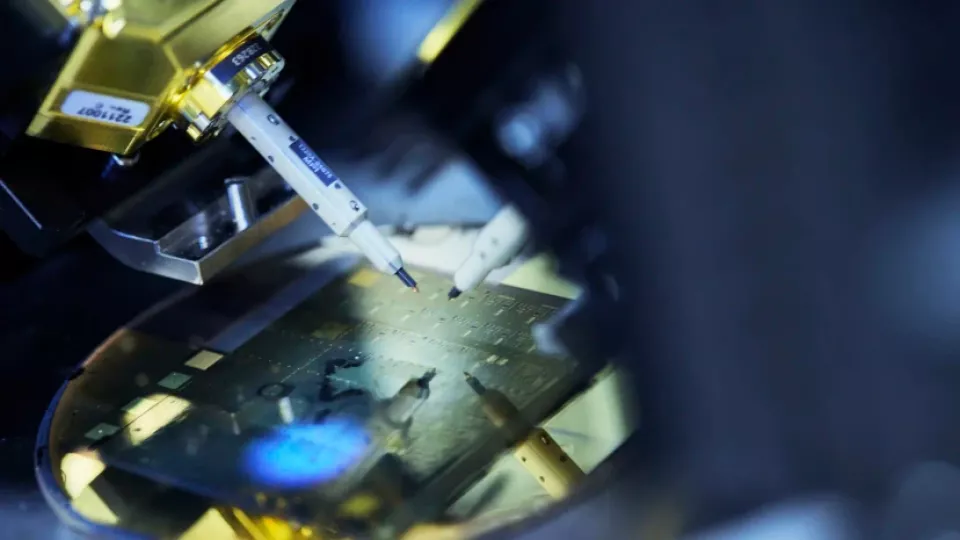

Electrum Laboratory and Albanova Nanofabrication Facility are the two laboratories operated within the KTH node of Myfab.

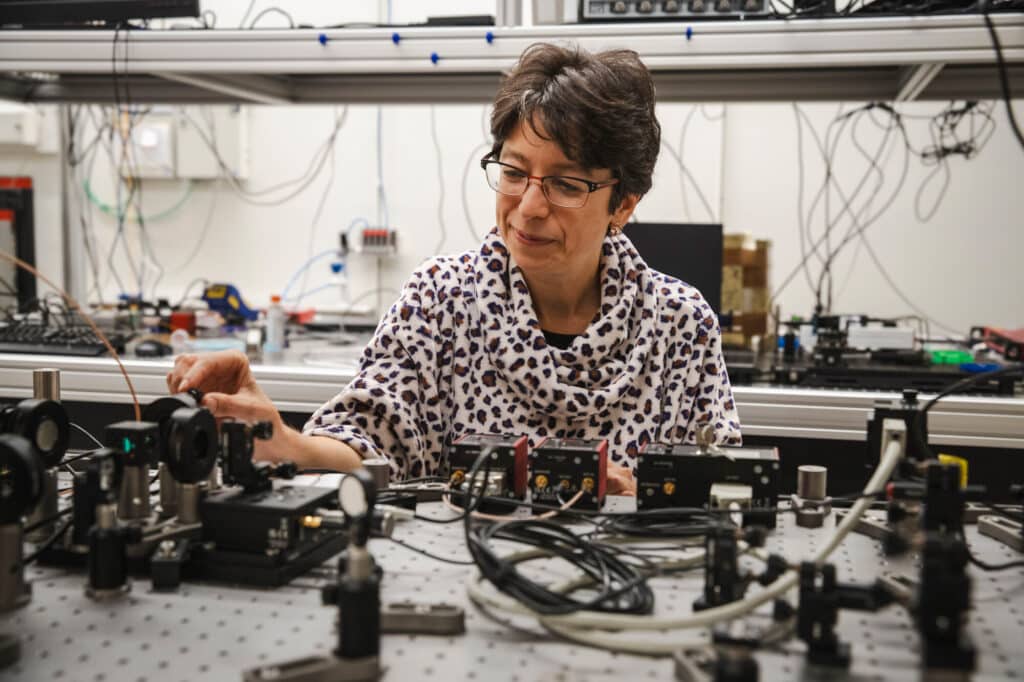

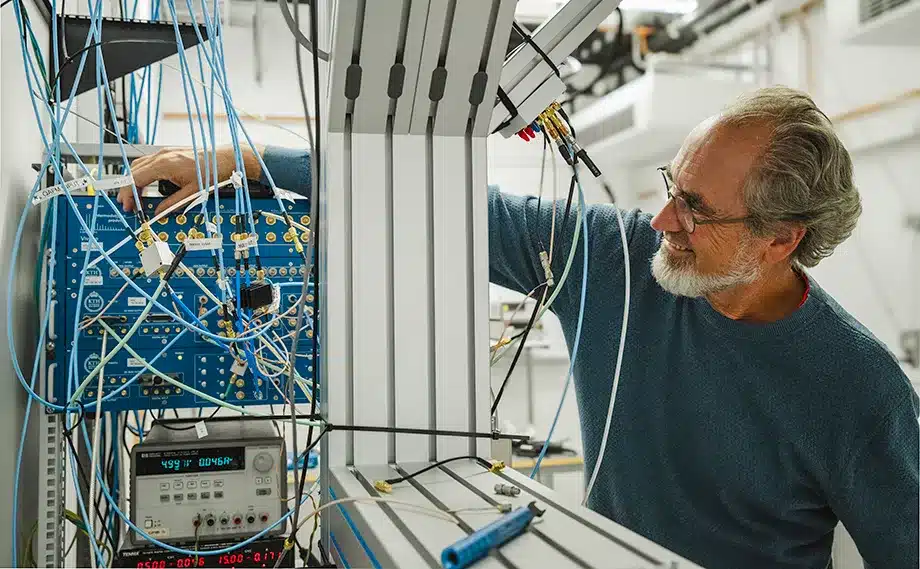

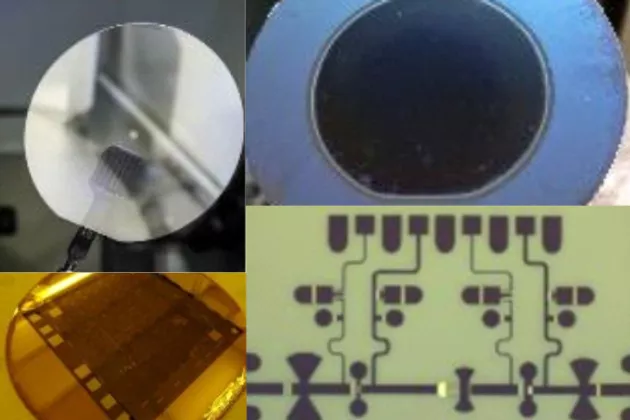

In Kista the Electrum Laboratory is outstanding for fabrication and characterization in the nano and micro scale, supporting the whole chain from education, research and development, to prototyping and production. From 2025 Electrum Laboratory is one of the nodes for the Wide Bandgap Pilot Line focusing on high voltage silicon carbide SiC power devices. The Electrum Laboratory has a long tradition of producing successful spin-out companies.

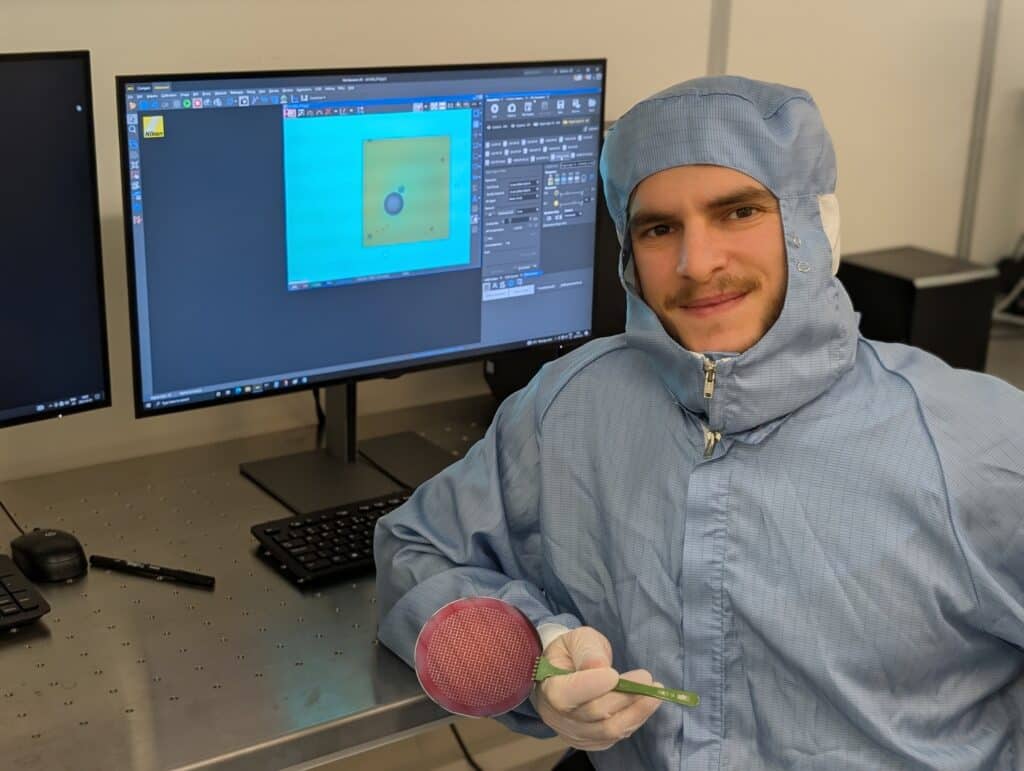

At KTH Campus the Albanova Nanolab focus on direct writing technology for academic and commercial nanoscale research and development, providing a flexible resource for basic research requiring fabrication and characterization for a wide variety of materials and substrate.

Contact

KTH, The Royal Institute of Technology, Stockholm, Sweden

Carina Zaring

+46 8 790 43 88

caza@kth.se